|

step one

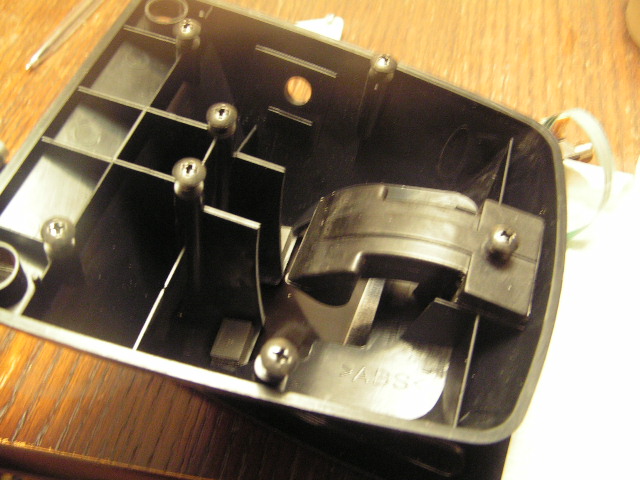

take off roland front box ..... be carful not to damage the ribbon cable.

remove heel spring(not needed)

take out rubber foot

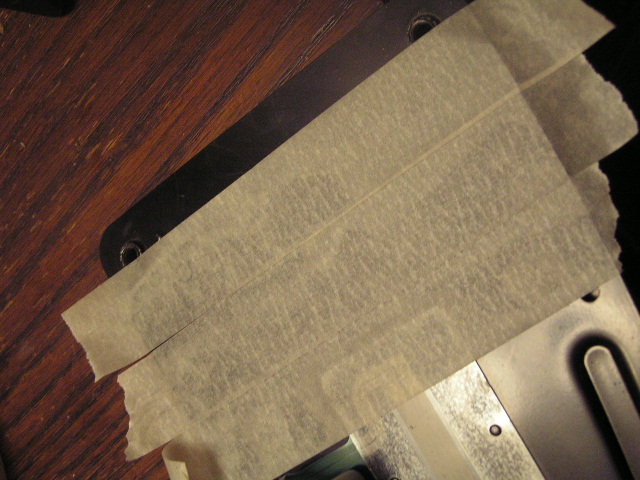

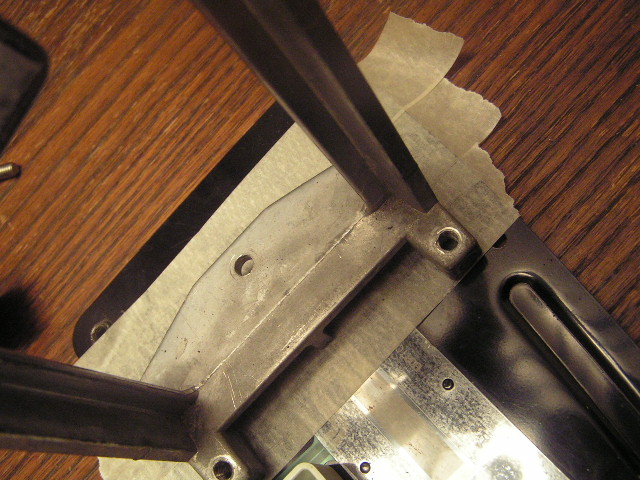

add masking tape to the end of the pedal so you can see the sensor and draw a few

drilling points

note hole drilled at front for extra grip...use a pen refill to get down in side the holes and mark

out hole positions

**at this point it is important that the rubber roller foot clears the front of the stand when fully depressed***

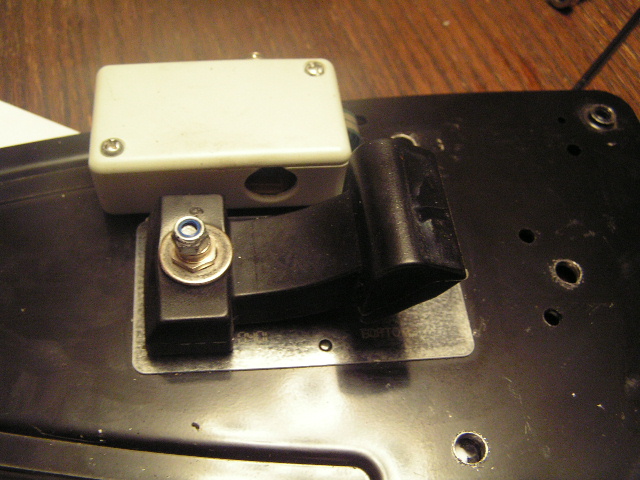

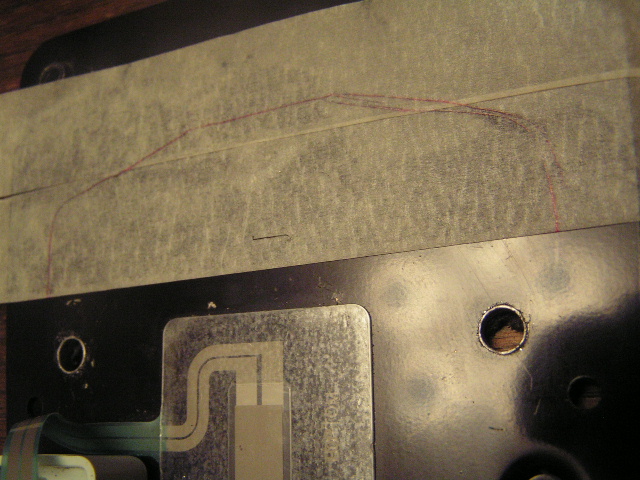

best mount the project box and jack at this point so not to damage it((note i got the hole

in the wrong side oops)((make sure the depressing plate does not hit this box

(the box could even be held on with a double sided tape pads ..but best with rivet or bolts .....?

cable hole has a cut away in it to let the cable pass through

i used a drum lug nut and a washer to fill out this hole in the rubber foot ...

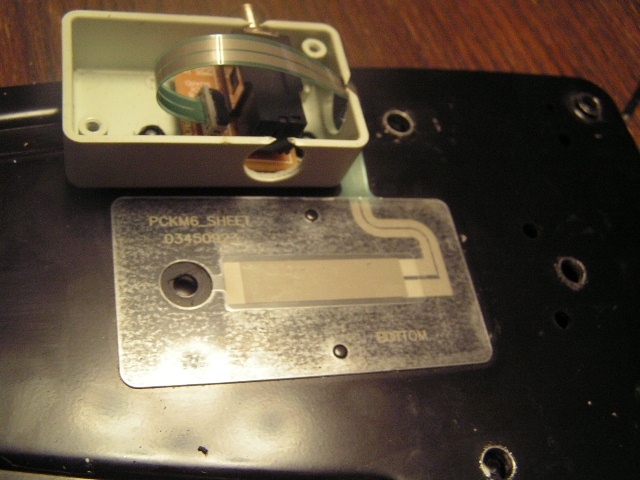

The FD normally suffers with dust getting under the foot

this version is easy to clean also to see what is happening while setting

up....dont forget to re grease the rubber foot.

remember the rubber foot or black pressure plate must not hit this cross bar

marking with pen re fill ....make these holes 6.5mm or even 7mm..the bolt will be 6mm but will be

going in at an angle

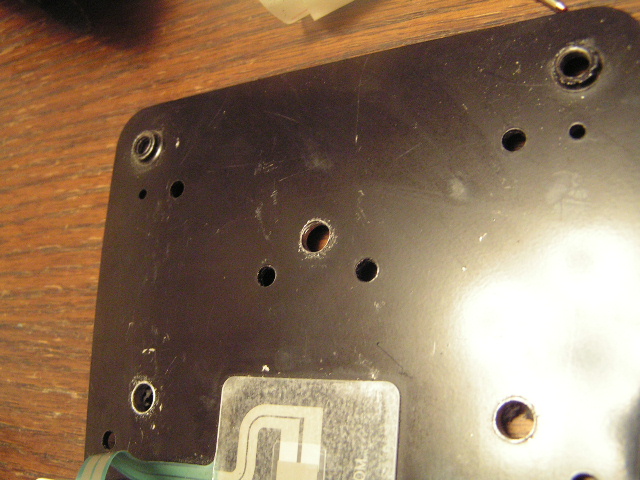

there we have 3 x 6.5mm holes ...the only other holes are 2x 4mm to hold the project box on

Make a Metal strip ..this is an old bit of alloy, it has 3 holes because i got it wrong frist time

:)

)but in the end i did use the holes at each end )))

55mm worked for me,again 6 mm holes.

it will need a bend in it

add your bar ..notice bolts ready to screw into hi hat stand

with last bolt and nut added

the bottom bolt on the pull rod is the anchor point of the whole stand make sure its locked

down hard to avoid rotation of the pull rod

there you have it.... thats as simple as it can be done i recon :)

built in A TEAM STYLE

using as little extra bits as possible....all stands are different so use the force luke

Enter content here

|